|

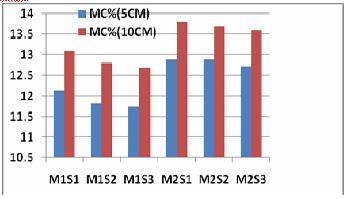

Figure 1. Soil moisture content (MC%) under different treatments at crop emergence |

|

Problem Statement

Pakistan has a very rapidly increasing population. Estimates indicate a near doubling to 243 million mouths to feed by the year 2025 (Jehangir et al, 2003). Moreover Pakistan is caught in the energy crises with very limited indigenous petroleum resources and a very high bill for imported fuels.

Since wheat crop is the staple food in Pakistan. It is grown on an area of 8 million hectares of the country. About 2.1 million hectares of the country are being used for rice crop growing (GOP, 1995-96). In rice-wheat cropping system the expensive land preparation by conventional methods for wheat sowing is not in access of any ordinary farmer. Nayyer et al. (l99l) reported that Rs. 300 per hectare were required for seed bed preparation. Mostly wheat sowing is delayed due to late vacation of rice fields, engagement of farmers in post harvest operations and time required for seed bed preparation by conventional methods. Consequently, Wheat yield is reduced and the money spent on inputs partially goes waste.

Keeping in view the energy crises issue and to avoid delay in wheat sowing after harvesting rice, there is a need of developing/modifying and field demonstrating seed drills which can drill seeds with minimum tillage and produce wheat crop with full potential in paddy growing areas. This will not only decrease cost of production but also increase food for the growing population of the country.

Objectives

- Fabrication of one unit of “Improved Boom Sprayer” and one unit of “Zone Disk Tiller Drill” for field plot demonstration

- Preparation of demonstration plots for physical operation of both the machines (Improved Boom Sprayer and Zone Disk Tiller Drill)

Methodology

The field study has been conducted at two sites; 1) PARS, UAF and 2) Agronomic Research Farm, main campus, UAF. Wheat crop was sown just after harvesting paddy crop in the standing residue fields in the growing season of 2009-10.

Eight acres at PARS and three acres at Agronomy Research farm were planted both by Old ZDTD and New ZDTD machines. Post emergence weed control was done chemically. Experimental data regarding soil moisture content, soil bulk density, soil penetration resistance at the time of sowing and crop emergence and seed emergence rate index were taken. The completely randomized split-plot statistical design (2-machines operated at 3-tractor forward travel velocities) with three replications was employed.

Results and discussion

Statistical analysis indicates that difference were observed in moisture content, soil bulk density, and soil penetration resistance before planting at both the 0-50 and 50-100 mm depth. The mean moisture content decreased with time both depths till the crop emergence began. This decrease in moisture content was definitely due to evapotranspiration of moisture.

Figure 1 depicts that low moisture content under M1S3 treatment at both the depths (5 cm and 10 cm) than those at all the other treatments could have been due to more soil loosening effect of M1S3 treatment (Improved machine speed 3).

The analysis indicates that bulk density decreased after planting at both the 0-50 and 50-100 mm depths. The mean bulk density was greater at 50-100 mm depth than that at 0-50 mm depth at the time of crop emergence indicating more soil loosening effect of treatments in the upper soil layer.

There were lowest bulk density values under M1S3 treatment at both the depths (5 cm and 10 cm) than those under all the other treatments. This could have been due to more soil loosening effect of M1S3 treatment (Improved machine speed 3). This proves the fact that loosens the soil, lower the soil bulk density, more the water evaporation and low the soil moisture content values.

The values of soil penetration resistance under M1S3 treatment were lowest than those under all the other treatments at their respective depths. This confirms the fact loose the soil, lower the bulk density, hence lowest the soil penetration resistance under M1S3 treatment.

The treatments M2S3, M1S1, M2S1, M2S2, M1S3, and M1S2 were found to have ERI in ascending order. The treatment M1S2 ranked highest and the treatment ranked the lowest in producing the ERI values respectively. This indicates that the improved ZDTD was found better at tractor second selected tractor forward speed.

Conclusions

Data regarding soil physical properties both before and after planting and crop germination has been collected and analysis discussed in the previous paragraphs. The farmer’s responses tregarding the crop stand and cheap method of crop sowing by ZDTD was greatly appreciable |